Your cart is currently empty!

“Super special 100% question”: WHAT IS TEXTILE (fabric)?

What is textile ?

(fabric)What is textile really, have you ever wondered?

But before I give you the answer to that question, I start this article, with a thought, a reflection.

Over the years, when I’ve talked to people about my work, I’ve noticed that a lot of them didn’t know much about the world of weaving, nor were they even clear about what a fabric was and especially how it’s made.

Lately I have also been searching a lot on the internet to see what information can be found about this area; with some amazement I have noticed that very little information can be found, especially the more technical information.

So I thought I’d try to fill that gap by blogging at Designs for Textiles about informative and technical articles on the subject.

In time I will also talk about the various and main techniques of weaving from design to production, making better known also the beautiful world of Jacquard fabrics, among the most difficult and beautiful to make.

I start this first article by starting from the basis of everything, giving an answer to a simple question, which, however, has an answer at bottom more “complex” than you might expect.

So, returning to the title of the article, What is textile?

If we wanted to simply define a fabric, we could say that it is an apparently “two-dimensional” object, since it is very fine in its third dimension, made from the interweaving of many threads that join together to create a soft surface, often also very resistant, and easily workable.

Let’s say that the definition alone, doesn’t really explain what a fabric is, and its real characteristics.

If you try to look at a fabric, especially the finest ones or those with a very compact surface, they might seem like large sheets of paper, very soft and malleable.

In reality, fabrics are anything but.If we looked much more closely at a fabric, using even a normal magnifying glass or even zooming in with our smartphone camera, we could well see that the surface of a fabric is very distinctive.

Although there are many techniques for making textiles, most are made from very fine threads that are woven together in various ways, and through this interweaving the fabric is created.

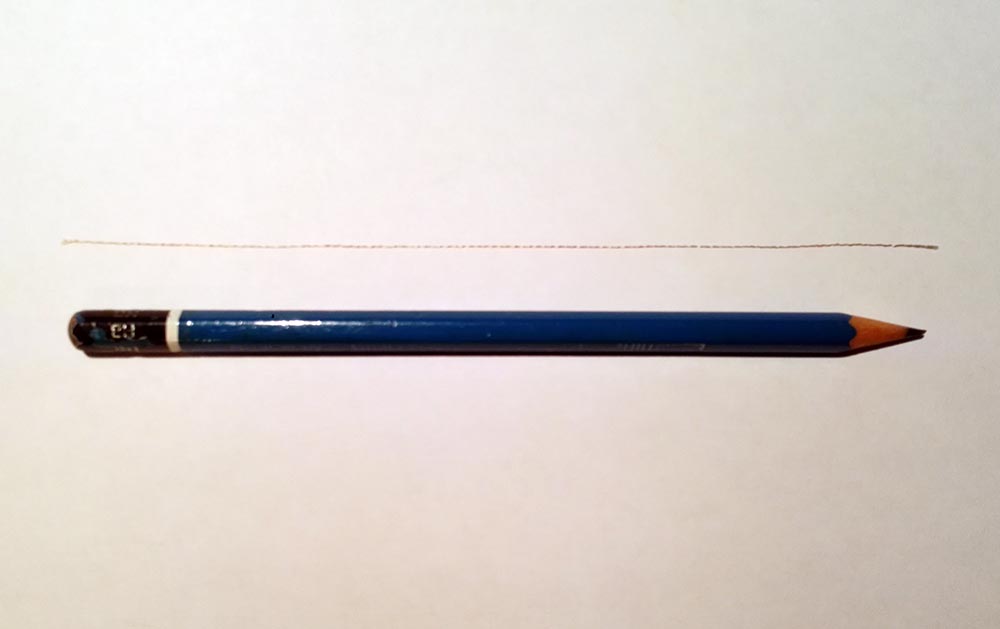

Look at the image below, what you see is a thread, specifically a silk thread.

As you can see by comparing it with pencil in the picture, it is really very, very fine, and it is from this thread that you can start to make a strong fabric with a surface also very compact, but still soft and easily workable.

In fact, at the base of the technique to make most of the fabrics we have a complex operation of crossing the wires arranged in a longitudinal direction with others arranged in a transverse direction.

The threads arranged longitudinally are called CHAIN OR WARP, and are wound on cylinders, now made of metal, once made of wood, called BEAM, which are then placed in the back of the machine used to create the fabric which is called: LOOM.

On the other hand, the threads arranged in transversal direction are called WEFT, and are those that are passed with various evolutions, through a special mechanism, between the various threads of the WARP, thanks to the LOOM, which creates the fabric.

But how is it possible for such a lightweight thread to move between the various warp threads arranged longitudinally creating a weave and consequently a fabric without creating a disaster?

Although the mechanism itself is quite complex I can explain it to you in a fairly simple way.

Do you see this object?

dav It’s called a SHUTTLE, it almost resembles a spaceship body, and in a way it could be “a spaceship”, but not for testing human beings, but threads, i.e. WEFT, one at a time, between the warp threads. Fascinating, isn’t it?

(I immediately want to point out that today with modern looms, no longer use the shuttle, but other systems that are based on the same concept.)But how does this shuttle manage to get each weft thread to the end of its “journey” without strange knots or breaks in the various warp threads happening?

in reality, the many warp threads are not stationary, because thanks to particular mechanisms they are moved up and down with predefined sequences that allow the weft, launched together with the shuttle by a mechanism, to intertwine with the warp threads.

At this point one might wonder… but if the warp threads are so light and soft, how can they manage to withstand the speed and air displaced by the shuttle launched toward them without creating a disaster?

The method that was invented a very long time ago is as ingenious as it is simple.

Do you have in mind the comb you use to comb your hair?

That’s it, the warp threads are passed from 1 to more in equal numbers through some sort of very long comb throughout the height you want to give a fabric.Thanks to the passage between the tensioners of this special comb the warp threads are kept parallel in a perfectly regular way, thanks also to a tension that is applied, and this allows to raise in an orderly and precise way all the threads at the passage of the shuttle and consequently of the weft.

This is what happens to allow the weft to be interwoven with the warp.

As you can guess therefore to make a fabric is something very complex.

The basic method that I have just explained, is not the only one, but it is the one used in most fabrics.Surely you have in mind that some fabrics have designs on their surface, in some cases they are printed as if it were on a sheet of paper, in other cases they are made with a special technique called: Jacquard.

From the next article we will delve into the fascinating techniques of fabric making!

See you soon!

If you think this article might be of interest to someone else you know, share it and you’ll be doing them a favor!